Unlock the power of streamlined Engineering, Procurement, Construction, Commissioning, Installation, and more with our one-stop platform for all things EPC. Connect with top EPC’s Contractors, Vendors, and Suppliers, stay up to date on the latest Equipment’s and Design Practices, and ensure compliance with industry Codes and Standards. Join us and take your EPC game to the next level!

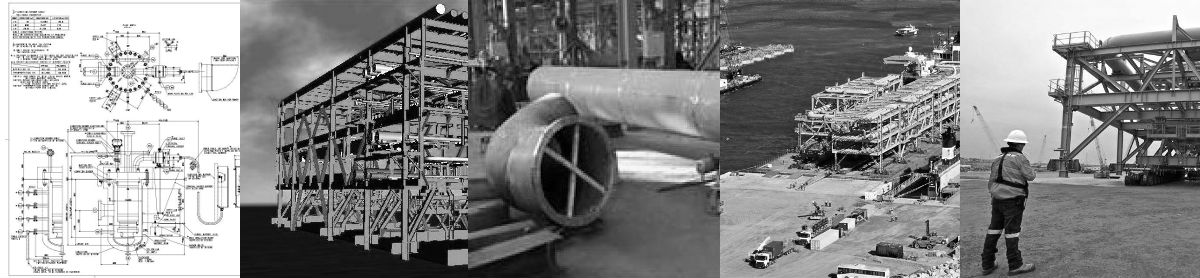

below is a glance of EPC…..

Engineering Procurement and Construction (EPC) is a type of contracting arrangement used in heavy industry. It refers to a process in which a company provides a turnkey solution for the design, procurement, and construction of a project. In this model, EPC contractors are responsible for all aspects of a project, from conceptual design and engineering to procurement of materials and construction of the facility.

The EPC model is typically used for large, complex projects such as offshore platforms, pipelines, refineries, and petrochemical plants. These projects are characterized by their size, complexity, and technical requirements, making the EPC model an appropriate solution for their execution.

Using the Engineering Procurement and Construction (EPC) model projects has several advantages. One of the key benefits is that it provides a single point of responsibility for the contractor who is responsible for the entire project, including design, procurement, and construction. This can simplify the project delivery process and reduce the need for coordination between multiple parties.

Another advantage of the EPC model is that it can lead to faster project delivery. EPC contractors often have the resources and expertise to complete projects more quickly than other contracting models. This is because they are able to manage all aspects of the project in-house, which reduces delays and increases efficiency.

The EPC model also helps to reduce risk for the owner. EPC contractors typically assume a significant portion of the project risk, which can give the owner peace of mind and allow them to focus on other aspects of their business.

Finally, the EPC contract usually includes a fixed price and timeline for completion, which can provide cost and schedule certainty for the owner. This can be especially beneficial for oil and gas projects, which are often large and complex, and can be difficult to predict.

While the EPC model has several advantages for projects, it also has its set of challenges.

One of the major challenges of using the EPC model is that it can be inflexible, as changes to the scope of work may require renegotiation of the contract. This can be an issue if the project requirements change during the course of the project.

Another challenge is the risk of cost overruns. Although the EPC contract includes a fixed price, there is still a risk of cost overruns if the contractor underestimates the scope of work or encounters unexpected challenges during the project. This can put additional financial pressure on the owner of the project.

The complexity of EPC projects can also be a challenge. They typically involve many different parties in the design and construction process. This can make coordination and communication more challenging, and can make it difficult for the project to stay on track.

Finally, the EPC contractor typically has a significant degree of control over the project, which can limit the owner’s ability to make changes or influence the project’s direction. This can be an issue if the owner wants more control over the project or wants to make changes that the contractor is not comfortable with.

The Engineering Procurement and Construction (EPC) model is different from other contracting models in the industry, such as Lump Sum Turnkey (LSTK) and Design-Build.

In the LSTK model, the contractor provides a fixed price for the entire project, but the owner is responsible for procuring materials and equipment. This means that the owner will manage the purchase of materials and equipment for the project, and the contractor will be responsible for the installation and construction of the facility.

In a Design-Build model, the contractor is responsible for both design and construction, but the owner is responsible for procuring materials and equipment. The contractor will design the facility and oversee the construction process, but the owner will need to purchase the materials and equipment needed to build the facility.

In contrast, In EPC Model, the contractor takes full responsibility for the entire project, including design, procurement of materials, and construction. The contractor is responsible for all aspects of the project and typically assumes a significant portion of the project risk, This can make it different from other contracting models.

An Engineering Procurement and Construction (EPC) contract is a legally binding agreement between the owner and the EPC contractor, that outlines the scope, schedule, budget and other terms of a project. The structure of an EPC contract typically includes the following elements:

- Scope of work: The scope of work is a detailed description of the project and the work to be performed by the contractor. It defines the overall scope of the project, including what is included and what is not included in the contract.

- Pricing: The pricing element of the contract defines the fixed price for the project and any contingencies or allowances for unknowns that may arise during the project. The EPC contractor provides a fixed price for the entire project, which includes costs for design, procurement, construction, and any contingencies.

- Payment terms: The payment terms specify how the owner will pay the contractor for the work. These terms typically include details on how the payments will be made, when they will be made, and how the progress of the project will be tracked.

- Schedule: The schedule is a detailed plan that outlines the timeline for completion of the project. It includes milestones, deadlines, and a detailed plan for the construction process.

- Performance guarantees: Performance guarantees are provided by the contractor to ensure that the facility will perform as specified in the contract. These guarantees may include warranties for the facility’s equipment, or guarantees for the facility’s production capacity.

- Termination provisions: The termination provisions outline the conditions under which the contract can be terminated. These provisions typically include details on how the termination process will work, and the consequences for the parties involved if the contract is terminated.

When selecting an Engineering Procurement and Construction (EPC) contractor, it’s important to consider several factors to ensure that the contractor is well-suited for the project and that the project will be completed successfully. Below are some key factors to consider:

- Experience: The contractor should have experience in similar projects and a proven track record of delivering projects on time and on budget. It’s important to verify that the contractor has the necessary experience to complete the project successfully.

- Resources: The contractor should have the resources and expertise necessary to complete the project, including a skilled workforce and necessary equipment. The contractor should have the personnel, equipment, and financial resources needed to execute the project safely, on schedule and within budget.

- Financial stability: The contractor should be financially stable and able to secure the necessary financing to complete the project. A financially stable contractor is better equipped to handle unexpected costs and delays during the project.

- Safety record: The contractor should have a good safety record and a commitment to safety on the job site. A contractor with a good safety record is less likely to experience costly accidents and delays, and more likely to prioritize safety in the execution of the project.

- References: It is important to speak with references from previous clients to get a sense of the contractor’s performance on previous projects. Talking with previous clients can give you insight into the contractor’s performance, reliability and professional behavior.

By considering these factors when selecting an EPC contractor, you can increase the likelihood that the project will be completed successfully, on time, and within budget.

Successful Engineering Procurement and Construction (EPC) projects in the industry require a combination of careful planning, effective execution, and ongoing management. Below are some best practices that can help to ensure the success of an EPC project:

- Clearly define the scope of work: A well-defined scope of work is essential for the success of an EPC project. This should include all the details of the project, including what is included, what is not included, and any specific requirements or constraints. It is important to involve all stakeholders in the scope definition process to ensure that all requirements are captured.

- Use an experienced EPC contractor: An experienced EPC contractor will have the resources and expertise to deliver a successful project. They should have a proven track record of completing similar projects on time and within budget, and have the necessary personnel, equipment, and financial resources to execute the project.

- Maintain good communication: Good communication between the owner, EPC contractor, and other stakeholders is essential for the success of an EPC project. It is important to establish regular communication channels and processes, such as regular progress meetings, to keep all parties informed and resolve any issues in a timely manner.

- Manage risk effectively: It is important to identify and manage risks throughout the project to ensure that they do not negatively impact the project’s cost, schedule, or quality. This may involve developing a risk management plan, and regularly monitoring and reassessing risks.

- Monitor project performance: It is important to closely monitor project performance to ensure that the project is on track to meet its cost, schedule, and quality targets. This may involve using project management software to track progress, conducting regular progress meetings, and performing regular quality checks to ensure that the project is meeting the required standards.

By following these best practices, you can increase the likelihood of a successful EPC project in the industry.

The shift towards renewable energy is having an impact on the Engineering Procurement and Construction (EPC) model. As renewable energy technologies become more prevalent, the EPC model is being used more frequently for projects such as solar and wind farms.

The EPC model is well-suited for these types of projects due to its single point of responsibility and fixed price structure. These features can provide cost and schedule certainty for the owner and ensure that the project is completed on time and within budget.

However, the EPC model may need to be adapted to account for the unique characteristics of renewable energy projects, such as the use of new technologies and the need to consider the impact on the environment.

Renewable energy projects often involves new and emerging technologies, like storage systems or smart grid integration, These new technologies can pose additional challenges for EPC contractors who are not familiar with them. Additionally, the EPC contractors need to consider the impact of their projects on the environment. This includes understanding the unique environmental impact of different types of renewable energy projects, and ensuring that they take the necessary steps to minimize those impacts.

Therefore, it’s important for EPC contractors who are working on renewable energy projects to have the experience and expertise required to manage these unique challenges, and be able to adapt to the changing requirements of renewable energy sector.

Please follow below link for detail of about